Engine technology requires cast parts of highest quality

In the field of engine technology, the Silbitz Group offers their customers efficient and holistic solutions. When it comes to the construction, production and assemblage of components in the field of engine technology, products of a high technical and quality standard are of a very great importance. The parts of the diverse cast materials for engine technology, like for example the cylinder heads, the cylinder covers, the pistons or complete engine blocks guarantee the highest process reliability for all important drawing specifications, due to the special and already proven manufacturing processes. From the development stage and the production to the logistics – our partners in the engine technology benefit from the quality, the reliability and the experience of our services.

Individual range of services for engine technology

The customers in the field of engine technology appreciate the diligent and on schedule delivery of all orders, as well as the labor, the endurance and the inventiveness of our trained employees. According to the wishes of our customers, engine technology cast parts can be processed and primed before they leave our warehouse. In our company philosophy, quality assurance, quality analysis and quality control are among the most important methods for ensuring smooth manufacturing processes. Besides diverse mechanical and technological controls, the available screening equipment and the training of our employees make it possible to check complete large series for cavities and other inclusions.

Engine technology: the parts and the customers’ expectations

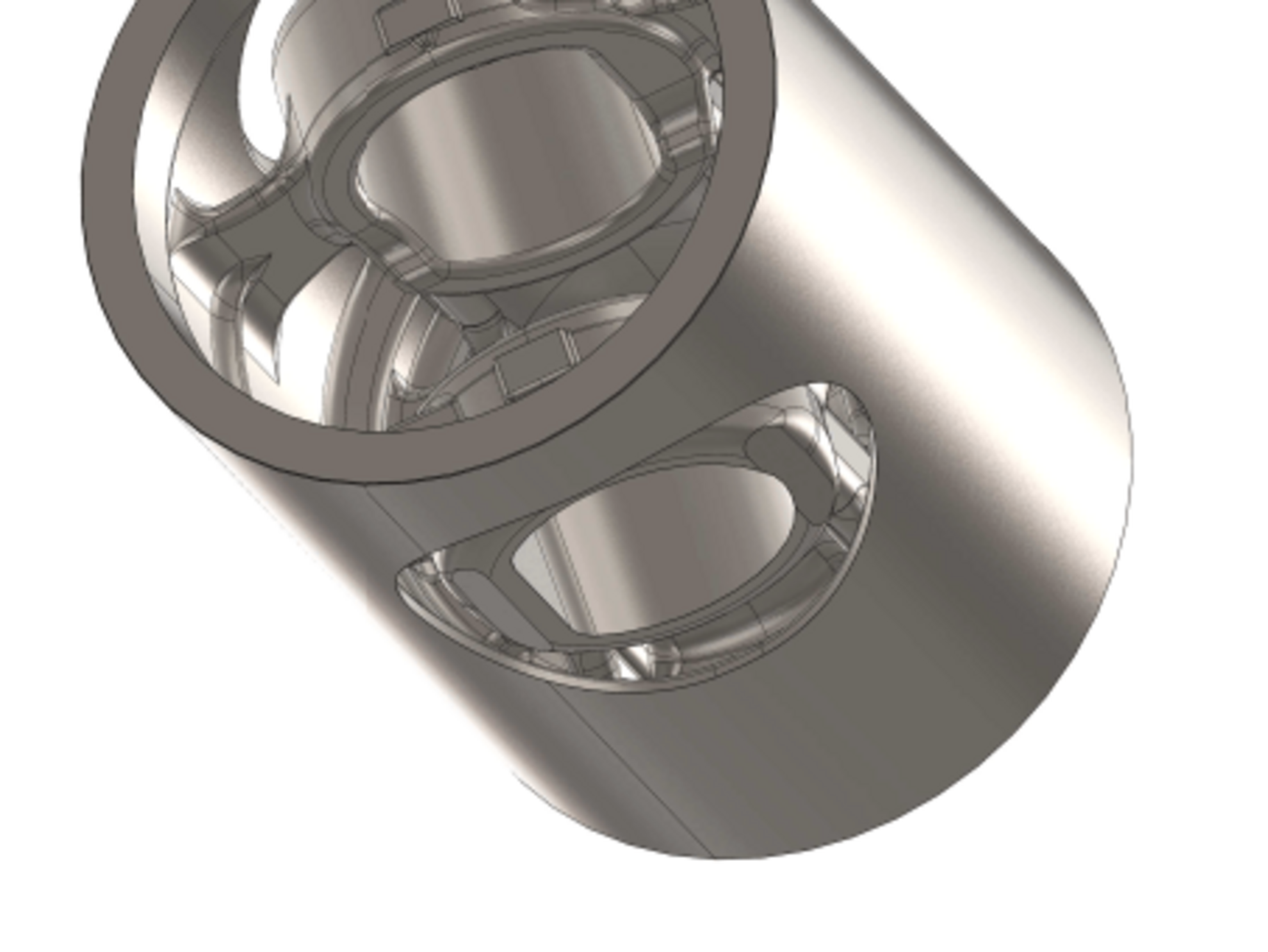

The production of cast parts for the engine technology is a demanding task. Precision, flexibility and the high qualification of all individuals involved are required. The construction FMEA is created through team work. It recognizes potential risks, which can cause serious disturbances or a breakdown of the engine after the installation of the products into the units of the customers already in the development phase of the engine technology parts, which could cause serious disturbances or a breakdown of the engine after the installation of the products into the units of the customers. As soon as the new parts are produced under series conditions, statistic methods are coming into use. The trained employees measure the functional drawing specifications of a certain number of parts and analyze them with the help of a special statistics program. Thereafter, the specific object is to optimize the processes and tools in such a way to achieve a zero error rate for the customer deliveries. After the installation into the diesel engines of our customers, an efficient fuel and oil consumption is as important to them as the high durability and the low noise level of the pistons made by us. In the engine technology, the pistons are of great importance for trains and large ships. They form the central unit of the diesel engine together with the cylinder lining, the piston rod and the piston ring. The customer can expect the highest quality, faultless deliveries on the right day and at the right place and a reasonable price when it comes to material technology, strength and the size accuracy. Through the innovative implementation of the results of research and development, we are able to provide these characteristics to our customers.

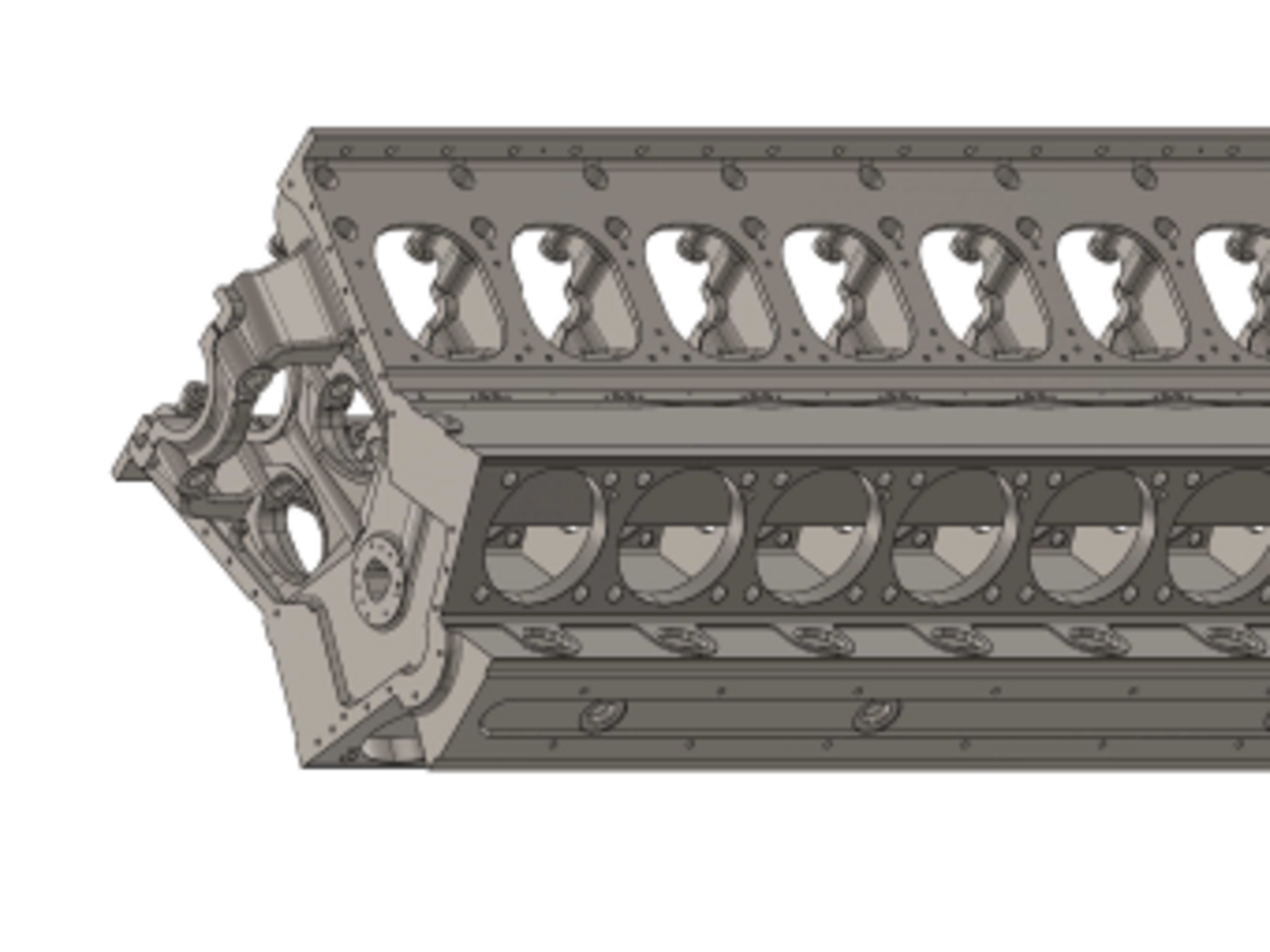

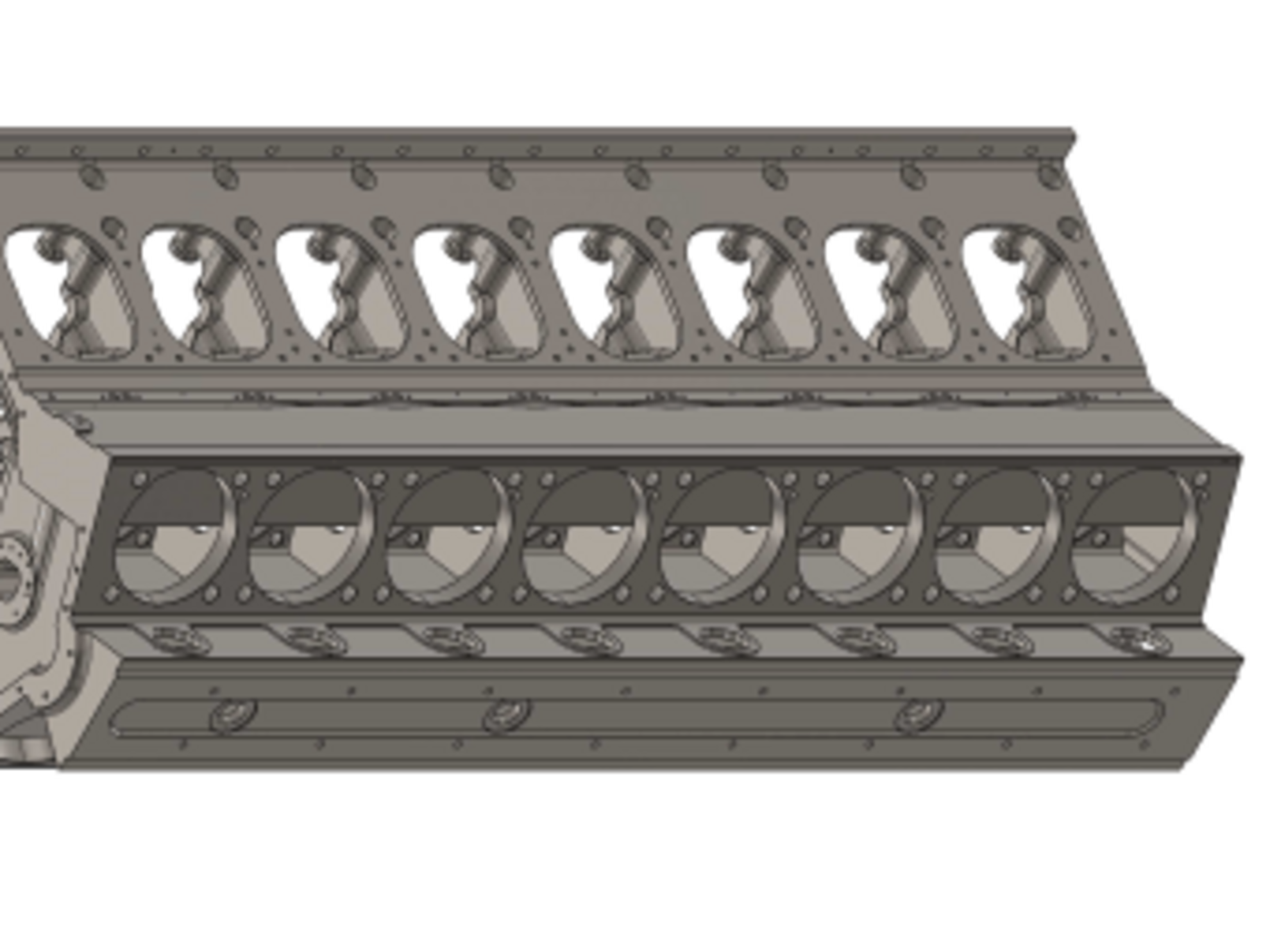

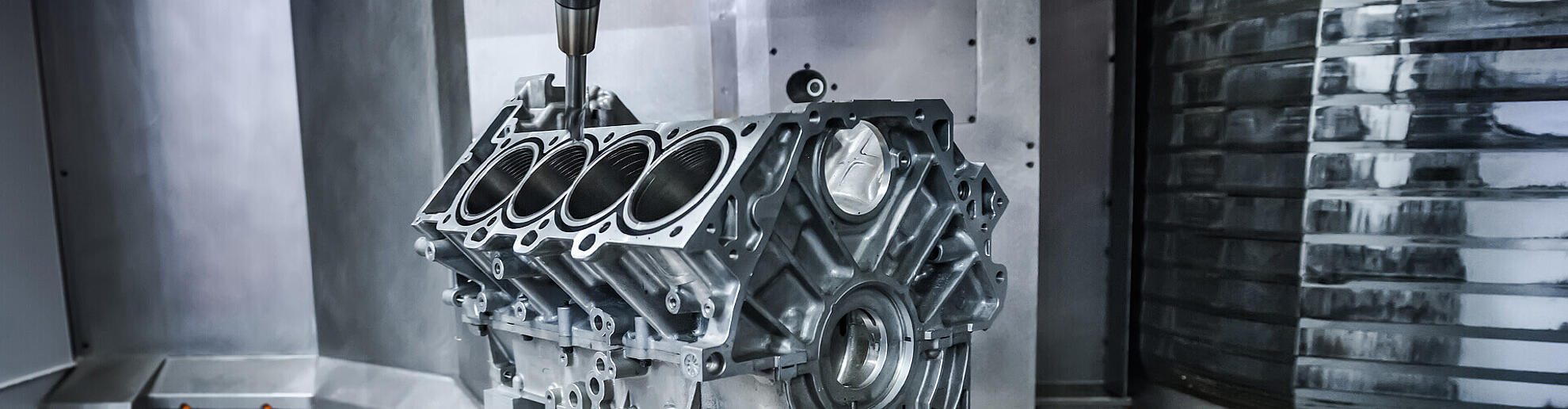

Engine technology in detail: the engine block

The engine block transfers the dynamic forces and stores the crankshaft. Together with the oil sump, it forms the end of the traction unit. As fastening aggregate for the cylinder head and their auxiliary units, it has to correspond to all drawing specifications.

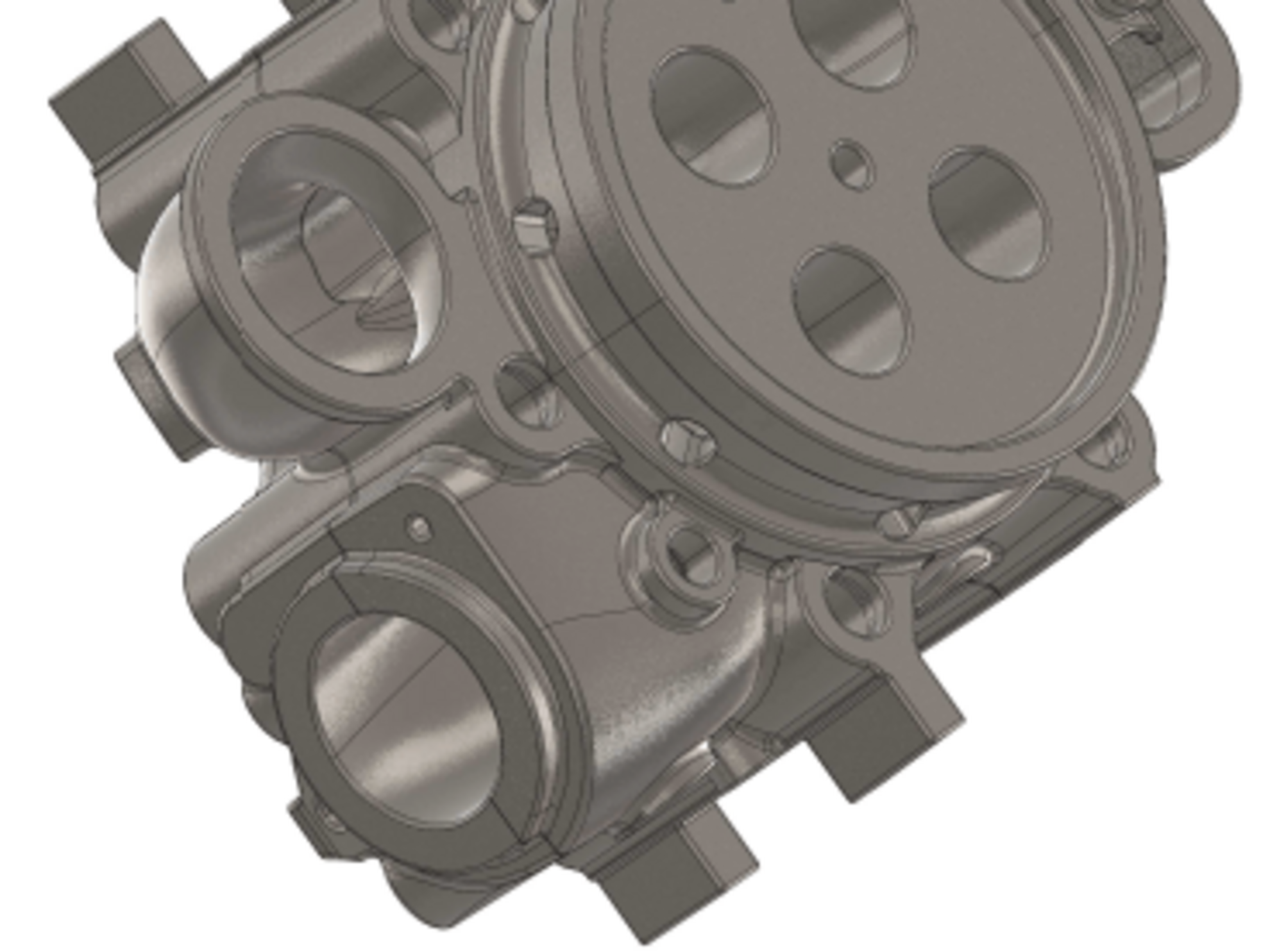

Engine technology in detail: the cylinder head

The cylinder head tops the combustion chamber of the diesel engine. Any small mistake in the size accuracy or the strength of the parts could cause serious disturbances or a failure of the entire system. As the cylinder head, besides the engine block, is one of the most complex components of a diesel engine, the most modern process and production methods are absolutely necessary.

Engine technology from Silbitz Group

As a result of our many years of experience in the engine technology sector we manufacture cast parts for diesel engines for large ships and locomotives as well as for stationary and mobile power generators. Highly complex cast parts such as pistons and cylinder covers can, if you wish, be supplied mechanically machined and delivered according to your wishes. In addition we are able to test large scale productions on our x-ray system unit.