Mechanical processing at the Silbitz Group

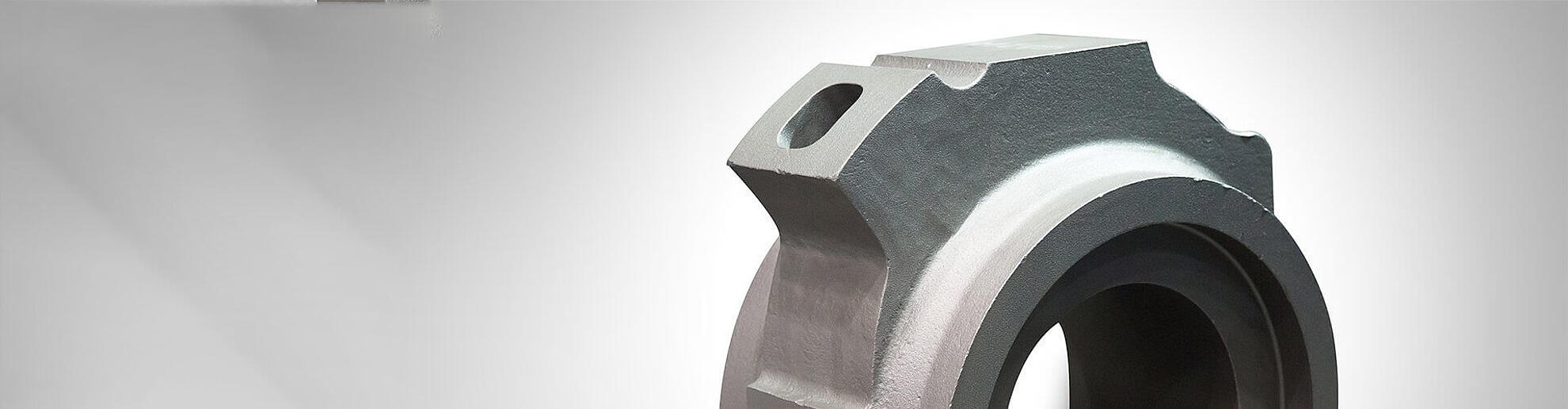

We as Silbitz Group GmbH are a traditional and innovative foundry company, which is able to produce ready-to-assemble cast components. We offer our customers consulting services in the area of construction, casting design and mechanical processing from a single source, without unnecessary loss of information and without unnecessary interfaces. In the meantime, a large number of our castings are delivered to our customers in single, small and medium series, pre-finished or finished. Our castings receive pre-processing from our mechanical processing department located in Silbitz, Germany. The pre-processing portfolio includes milling, drilling and turning the castings to customer specifications. Individual technical advice and support are part of our customer service.

Your advantages at a glance

Due to the extensive machine park for mechanical processing at the plants Silbitz Guss GmbH and Silbitz Group Staßfurt AWS GmbH, become customers - and production-related changes in the upstream and downstream processes are technologically and technically integrated in a timely manner. Quick feedback from the area of mechanical processing into the foundry's manufacturing technology also helps to incorporate optimizations into the process chain for casting production. For you as our customer, this means:

- Close cooperation between casting supplier and processor

- Time and cost reduction for administration and logistics

- shorter response and delivery times

- greatest flexibility

- high optimization potential

- modern machinery

- qualified personnel.

CNC-controlled machines and machining centers

In recent years we have constantly modernized our machinery, not least through the acquisition of Silbitz Group Staßfurt AWS GmbH The depth of production and flexibility are significantly increased. The machine park at the locations in Silbitz and Staßfurt includes a total of more than 40 modern CNC-controlled machine tools, including turning and milling machines from well-known manufacturers, which provide a wide range of turning and milling work in the area of casting processing for our customers. The possibilities for metal-cutting mechanical processing are diverse. Our processing locations manufacture on CNC machine tools that are state-of-the-art. The use of modern processing technologies ensures that the mechanical processing of the castings can be carried out economically and according to customer specifications. Through targeted investments and technology development within the KVP team, innovative machining strategies are further developed and implemented into the existing manufacturing structures.

The experience, commitment and flexibility of our employees contribute significantly to our company's success. In addition to the annual training and further education of our employees, a separate training center was created in 2016 in which the profession of cutting machine operator is trained. Own and, above all, practical training enables employees to prepare for company-specific tasks and special features during their training. We therefore see the investment in solid skilled worker training as the foundation for a successful future for Silbitz Group GmbH.

Surface treatment according to customer requirements

In addition to mechanical processing, we can carry out customer-specific surface treatment for pre- and final-machined parts. We apply the appropriate primer and paint to the washed and cleaned surfaces according to customer requirements. Our customers therefore receive high-quality, pre-processed and ready-to-install products.

Benefit from our know-how as a complete supplier of ready-to-install castings and transfer your responsibility for high-quality and on-time delivery to us. In addition to processing our castings, our broad range of machines at the locations in Staßfurt and Silbitz are also available for contract manufacturing. We are a competent partner for machining tasks of all kinds and certified according to DIN EN ISO 9001. If we cannot technically or capacitively carry out processing tasks with our existing machines, we supplement our wide range of processing services through close cooperation with specialized partners. Due to our know-how in the field of mechanical processing, we are also happy to take on support for you and, as part of our supplier development, look for the right partner for the corresponding processing task.