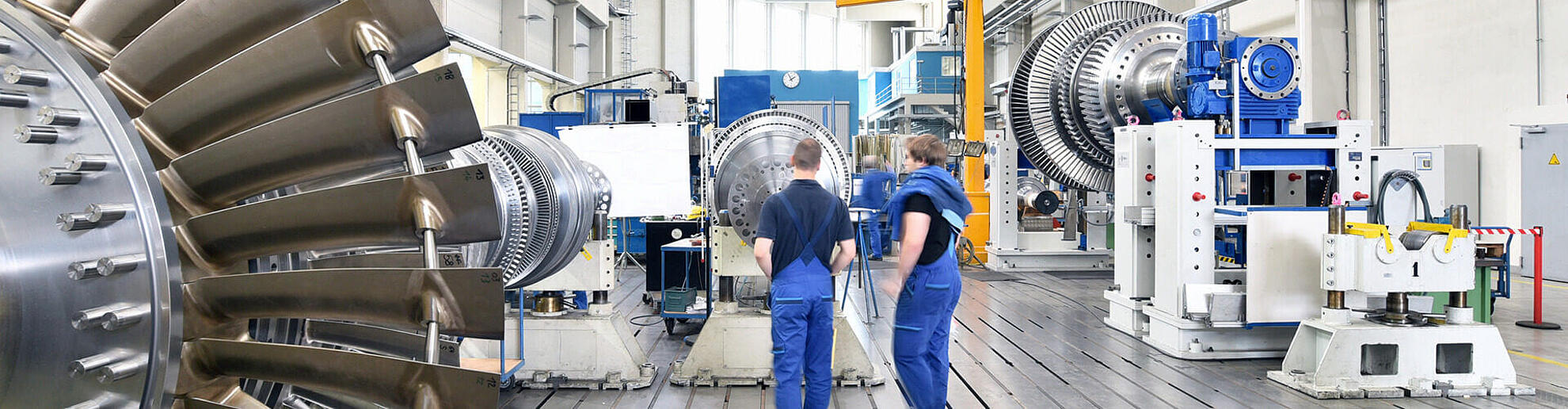

Energy technology - The Silbitz group is your reliable partner

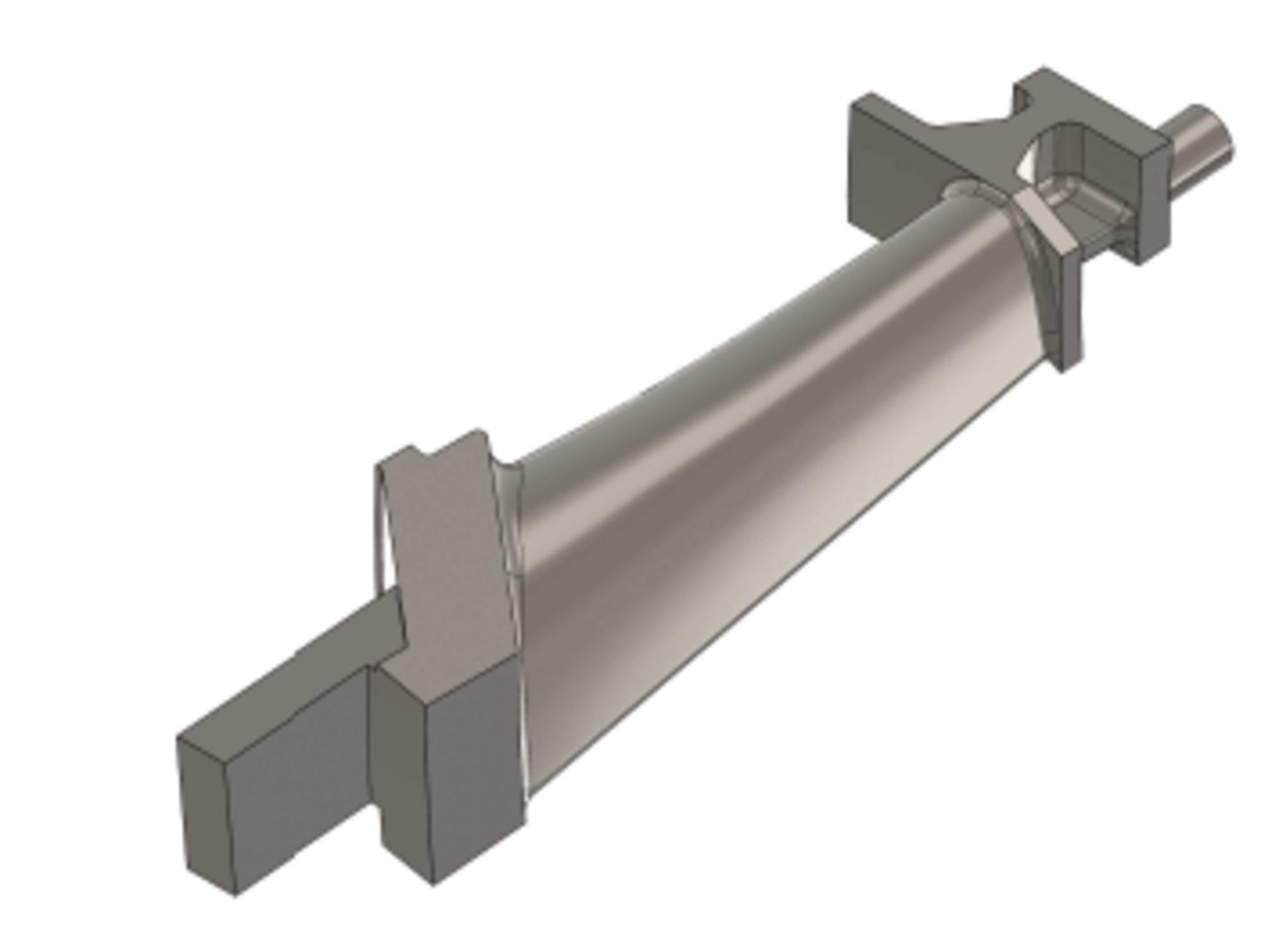

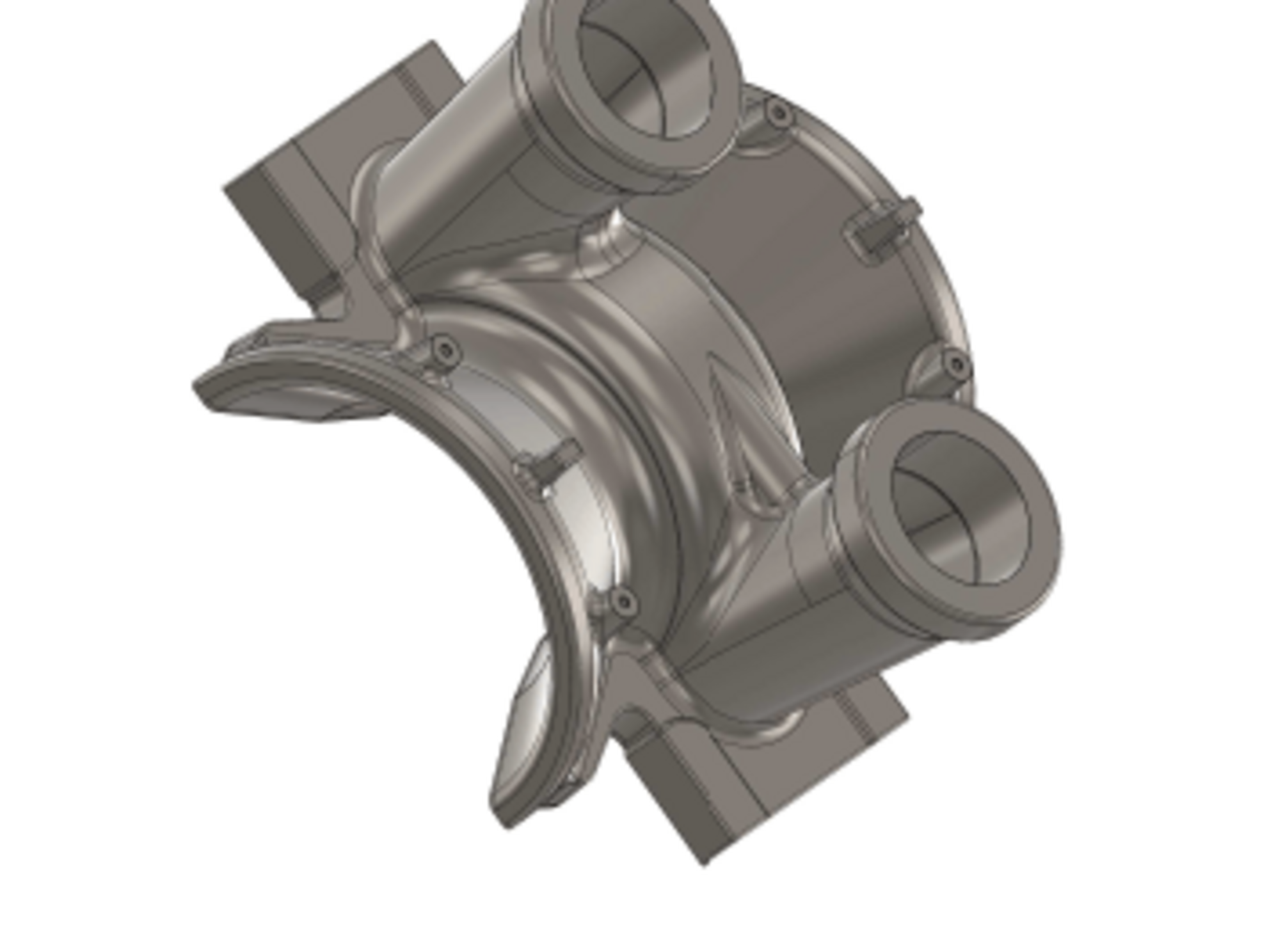

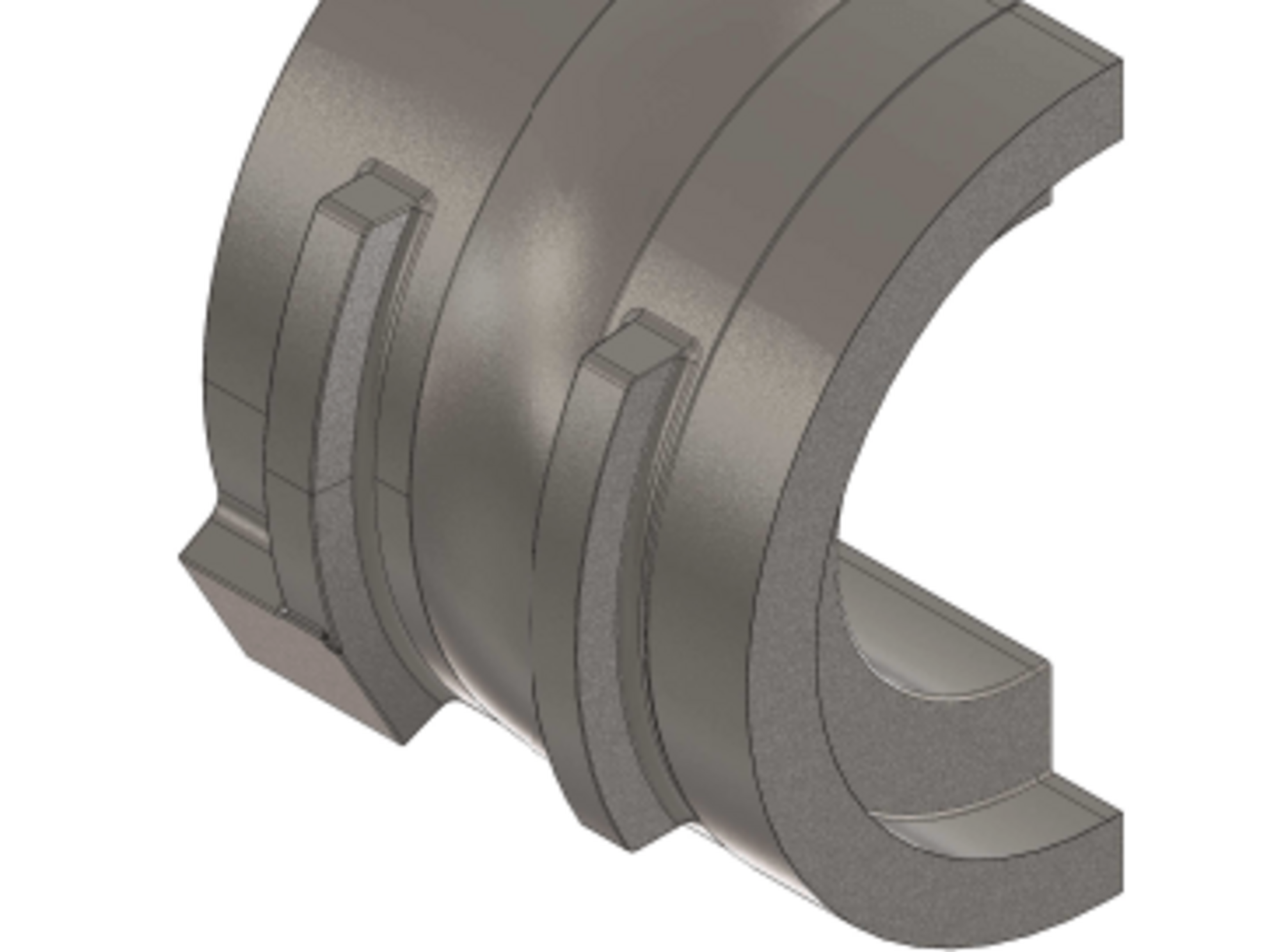

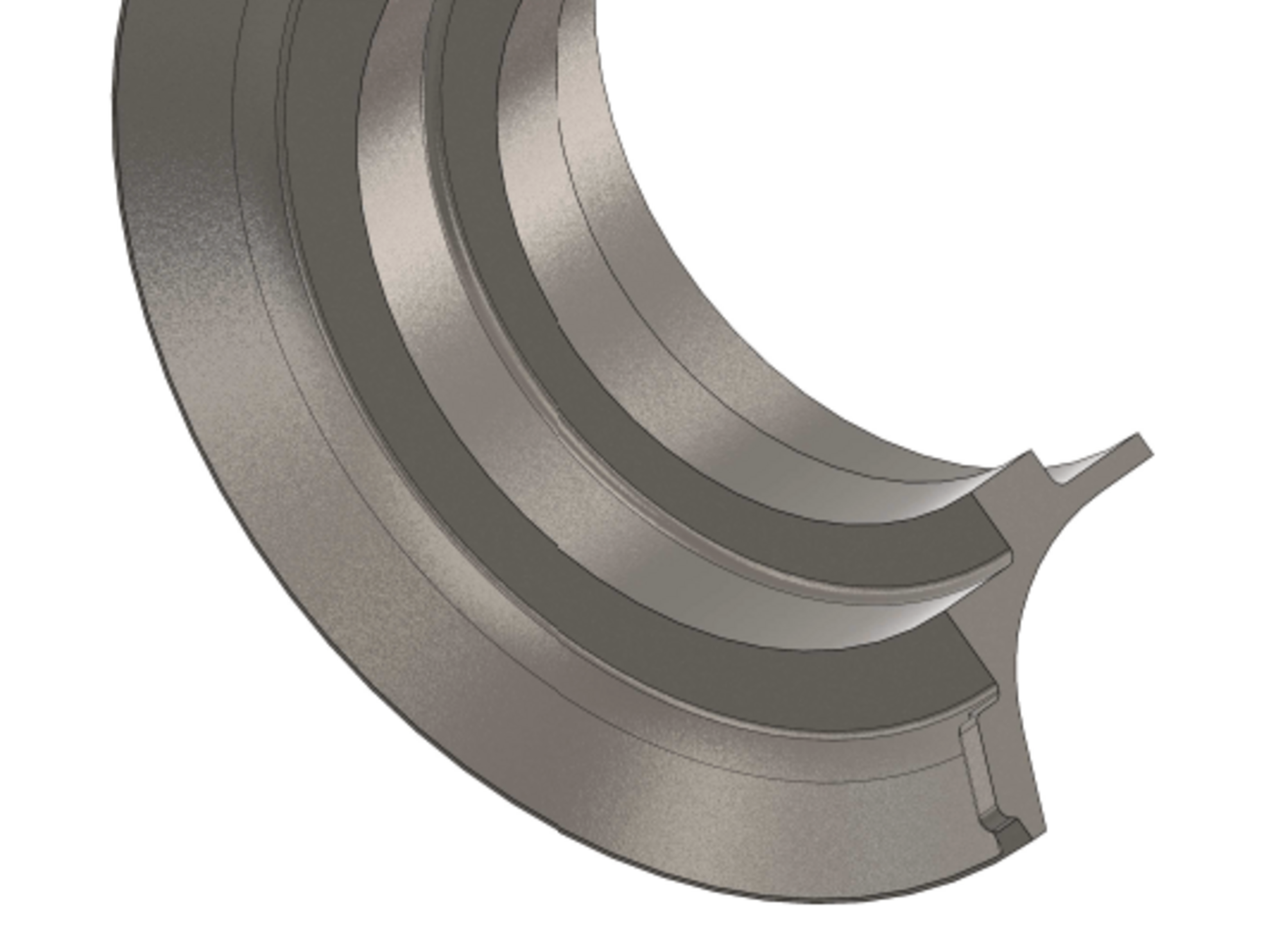

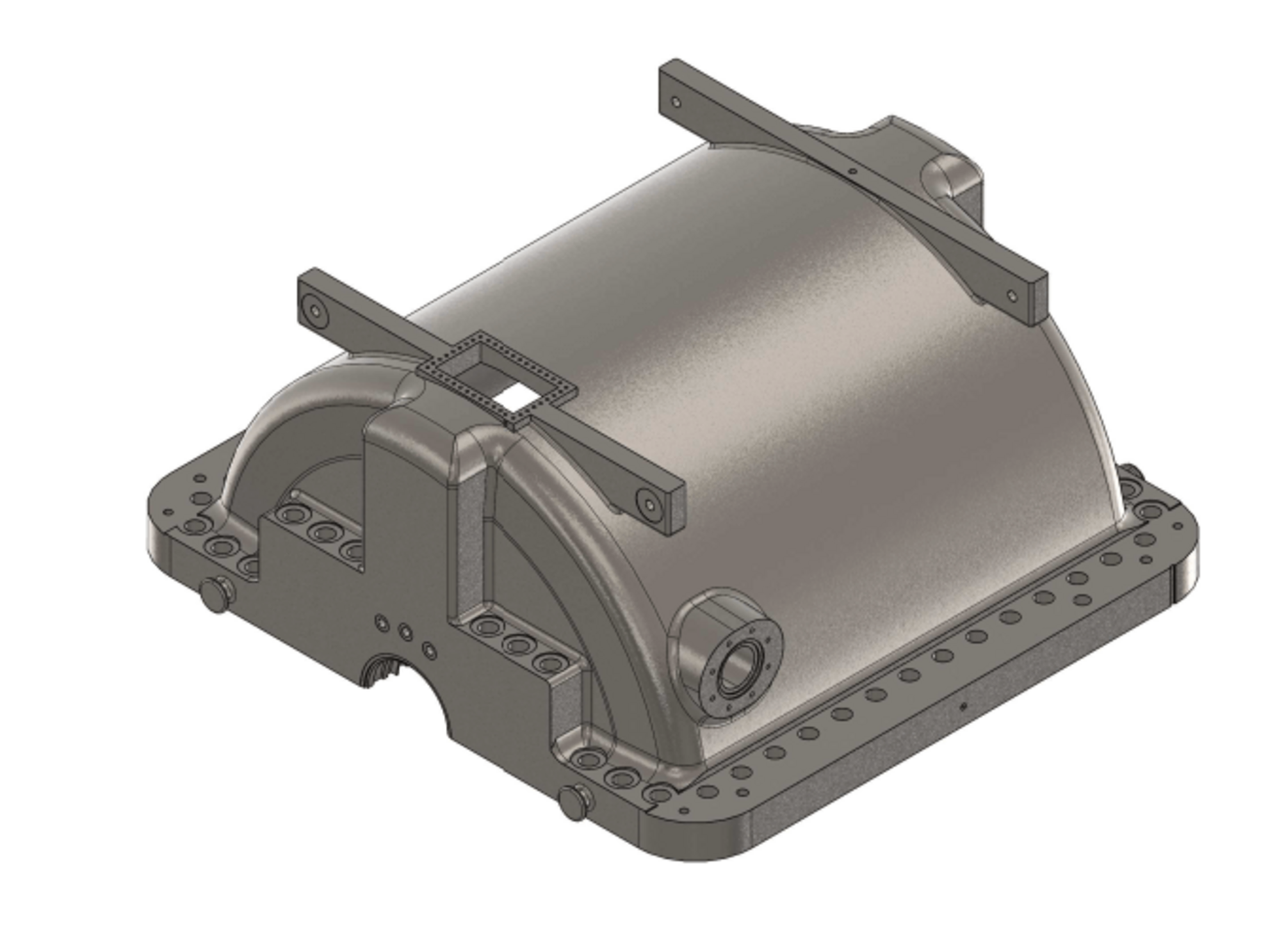

Together with customers of energy technology, the Silbitz Group develops enduring overall concepts to meet these demands in order to turn them into reality. Quality features such as strength and longevity have high priority. The repertoire of cast materials that the Silbitz Group can supply includes standard cast iron with lamellar and spheroidal graphite, as well as vermicular graphite cast iron, which must be classified between the first to, according to its mechanical properties. Furthermore, also austentic cast iron (Ni-resist) and the so-called austempered ductile iron (ADI) are offered. The castings produced at the sites in Silbitz. Kosice and Zeitz range in weight from 10 kilograms to 45 tons. Cast steel is mainly produced at the main site in Silbitz, with weight from 100 kilograms to 9,000 kilograms (tons). For the production of the castings, various facilities of the foundry plants are used. These include moulding equipment, a mechanical hand-moulding shop and hand-moulding shops. Which one of the devices is used, depends on the requirements and the size of the component.

Castings in energy technology

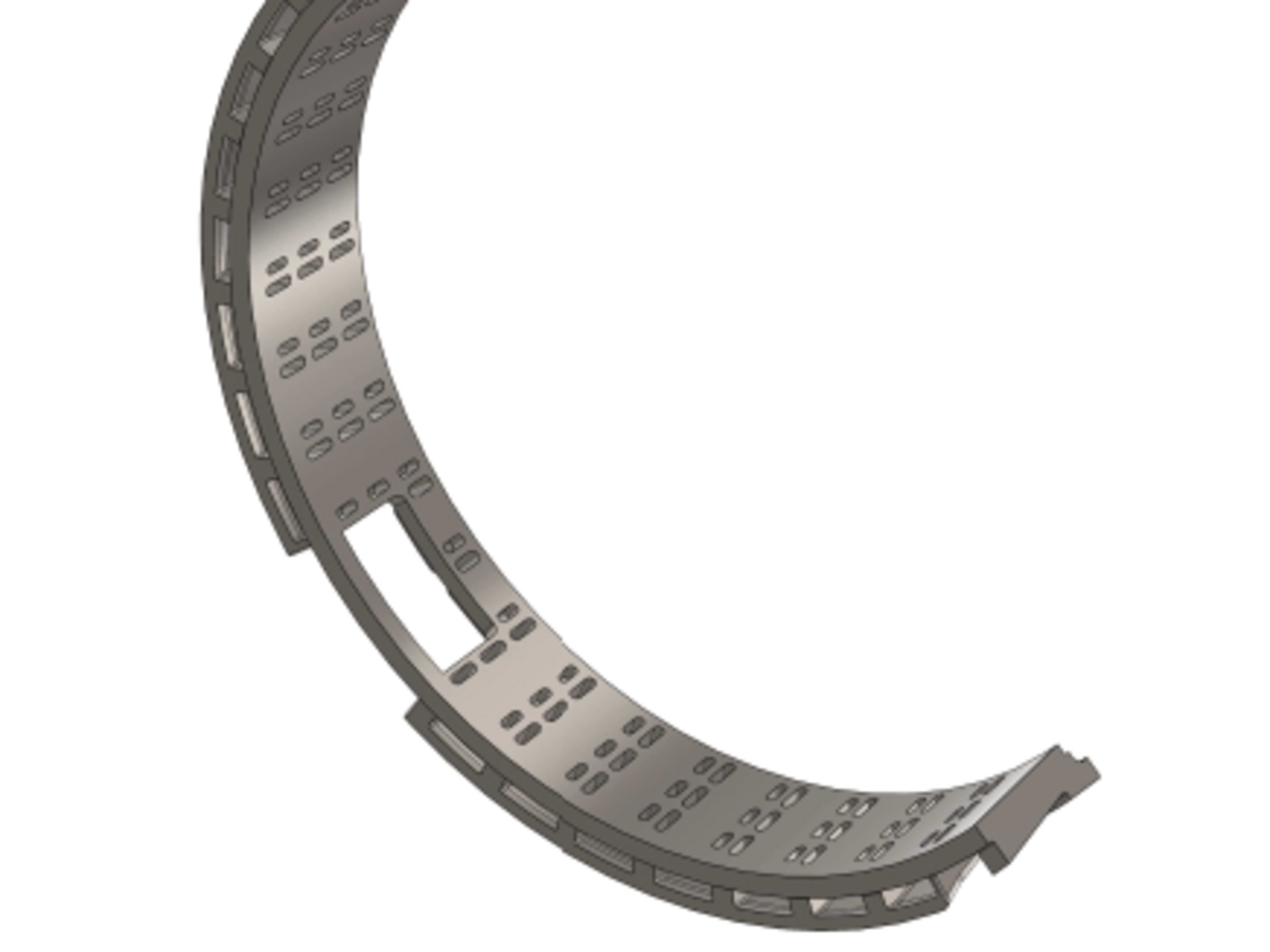

Energy technology is a science that includes the extraction, transformation, transportation, storage and use of energy in all its forms. Therefore, the energy technology is becoming more essential and would not be possible without the use if castings. Achieving high efficiencies is very important, which is why castings are often beneficial. They are used in particular, where components are needed that have to withstand high temperatures and pressures. If high efficiencies are to be achieved, sophisticated castings for gas and steam turbines adapted to the situation are a must in the energy technology.

Castings in energy technology

Energy technology is a science that includes the extraction, transformation, transportation, storage and use of energy in all its forms. Therefore, the energy technology is becoming more essential and would not be possible without the use if castings. Achieving high efficiencies is very important, which is why castings are often beneficial. They are used in particular, where components are needed that have to withstand high temperatures and pressures. If high efficiencies are to be achieved, sophisticated castings for gas and steam turbines adapted to the situation are a must in the energy technology.

We offer individual and tailor-made offers on the subject of energy technology

The Silbitz Group is able to provide all welding process tests for the welding of cast steel. There is also the option to meet custom-specific requirements by purchasing additional welding procedure tests. In addition to all traditional energy technology materials, we are also able to produce SiMo materials (silicon molybdenum) and Ni resist and also weld them. Due to our highly qualified personnel and most modern testing technology, the company also meets the high testing and documentation requirements placed on energy technology. The Silbitz Group is therefore the point of contact for large energy companies when it comes to reliability and a long-term partnership, all cast components should meet the highest quality, testing and documentation requirements and welding process test of any kind are required.

We look forward to making you an unbeatable offer.