Construction machinery and mining – description and definition

The technical requirements in the areas of construction machinery and mining have increased in the last few years. Castings of the highest quality grade are used in various areas of construction machinery technology and mining. The focus is on stability at maximum stress, precision in terms of function and fit as well as optimal material selection. The production of construction machinery technology and mining products is based on various casting processes and can be implemented up to a total wight of 9 tons.

Comprehensive range of services in construction machinery technology and mining

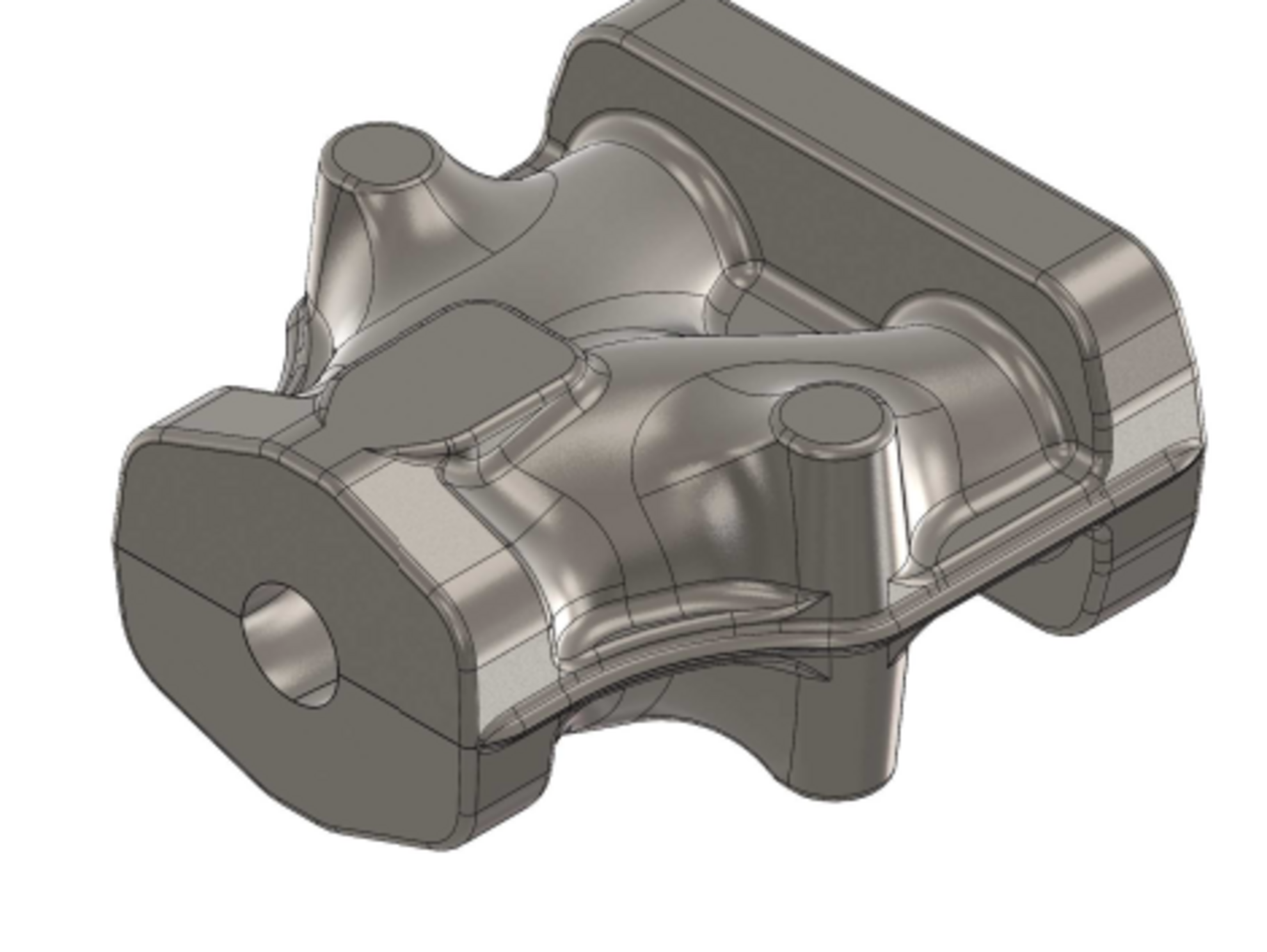

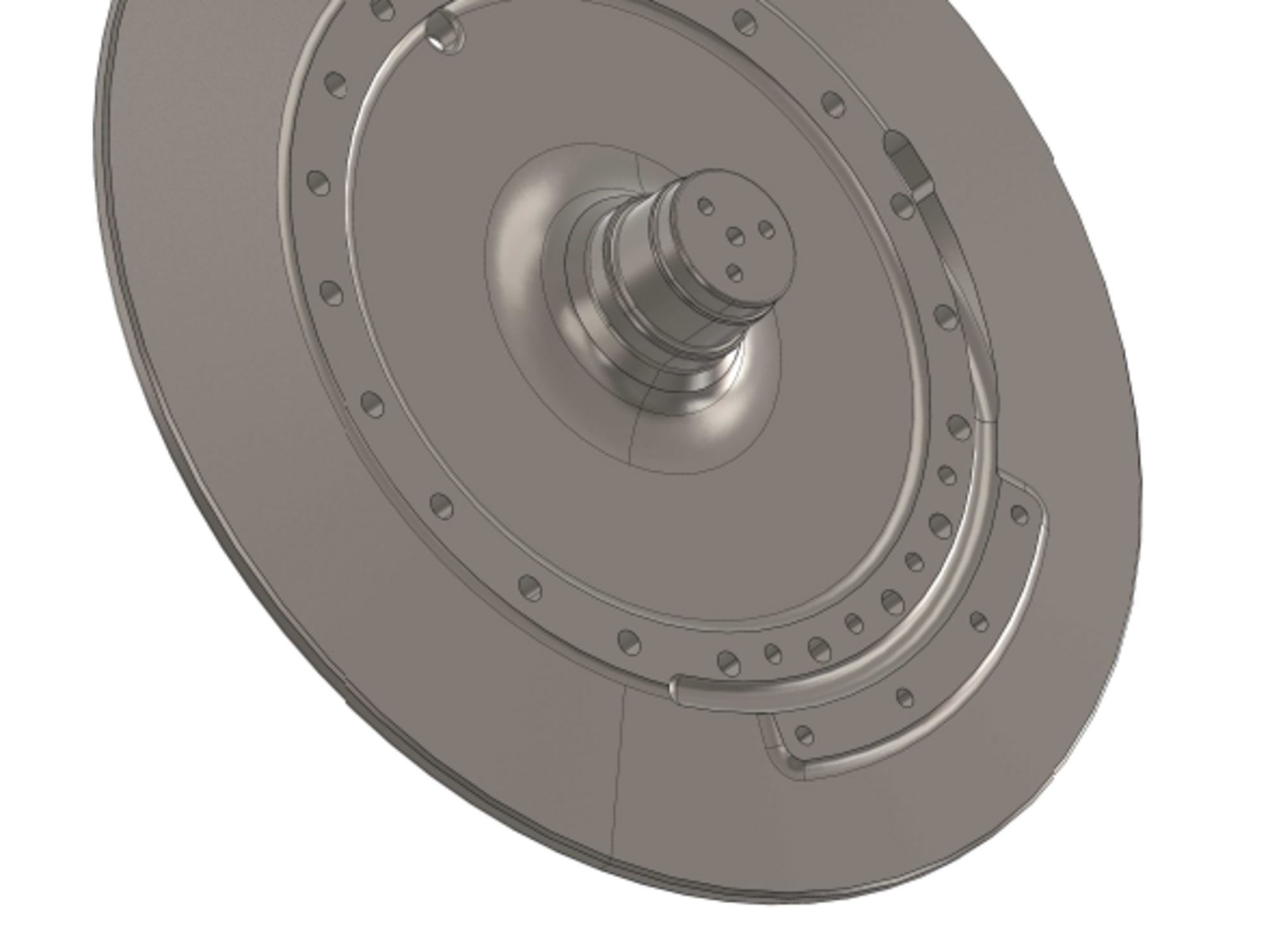

Tumblers and idler wheels, hub rollers and suspension axles or end discs are among the most frequently ordered parts in the field of construction machinery technology and mining. Furthermore, housings, cable drums and retaining rings, bearing flanges and wheel hubs are manufactured in casting processes and developed for use in construction machinery technology. Alloyed cast steel is used for most parts of construction machinery technology and mining. This material is characterized by its corrosion-free properties, high load capacity and low wear. In addition to the casting, the range of services for construction machinery technology and mining includes the mechanical finishing of the finished parts as well a the treatment of the surface for complete weather resistance and longevity.

Castings of the highest quality

In construction machinery technology, as well as in mining, quality is top priority. Break-resistant, non-corrosive and low-wear materials provide the best performance and ensure trouble-free, high-performance use. For the constantly high quality, the entire production process is subject to quality control at regular intervals. This does not apply to random sampling, but to the examination of each part.

Experience and competence in construction machinery technology / mining

Many years of experience and the use of most modern technologies and tried-and-tested processes underpin the quality characteristics of all parts manufactured by the Silbitz Goup in construction machinery technology and mining. Competence and expertise in simulation and design, in model making and in casting, as well as in quality control and logistics, offer a full-service concept according to customer requirements and area of application. For use with large excavators, mining trucks and general drilling technology, shape, dimensions and materials must not only be selected optimally, but also with precision. For this, the Silbitz Group supports you with words and deeds.

Professional construction machinery technology in use

The manufacture of products in construction machinery technology or mining requires expertise and know-how, knowledge of materials as well as professional skills in simulation and design. For long-term use under difficult conditions and continuous use in different weather conditions, alloyed steel is the preferred material. Construction machines are only as reliable and functional as the individual parts, which are manufactured using the casting or model forming process and designed to meet the requirements in use.